Mechatronic Integrated Devices (MID)

one, two, three and two become one

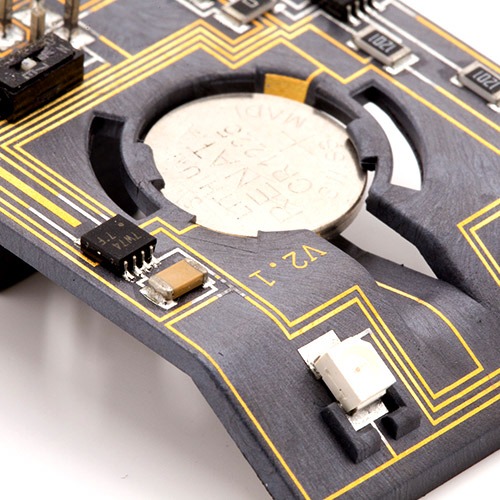

Mechatronic Integrated Devices are injection moulded circuit carriers. This principle is used to integrate an electronic circuit into a plastic mechanical assembly.

Example applications include seat control systems and the steering wheel vector group in a motor vehicle. Another application is the integration of an LED light element into a conventional lamp holder, such as the lighting systems for dental drills and hand grips.

The term MID refers to the production method and the component function. If the circuit carrier is 3-dimensional, this is referred to as 3D MID, i.e. “three dimensional injection moulded circuit carriers”.

The traces are applied to the carrier using various methods. The latest and most flexible method is the laser structure method, which is used by CiS and their partner.

Additional benefits of MID include:

- Integration of electronics and Mechanics into a single assembly

- Miniaturisation

- New functions

- Any shapes can be designed

- Reduction of the number of parts

- Reduction of the variety of materials

- Lower material consumption

- Material recycling

A distinguishing feature for MID by CiS and their partner is the development and production of usable samples within a short period of time. This has the benefit of considerably reducing the time to market of new developments.