Flat Ribbon Cable: The Smart Choice for Compact and Powerful Connections

Flat ribbon cables are frequently used in electrical engineering. We’ll show you how this type of cable is constructed, which industries use it, and why our professionally customised solutions are the right choice for your application.

The Smart Choice for Compact and Powerful Connections

Flat Ribbon Cable at a Glance

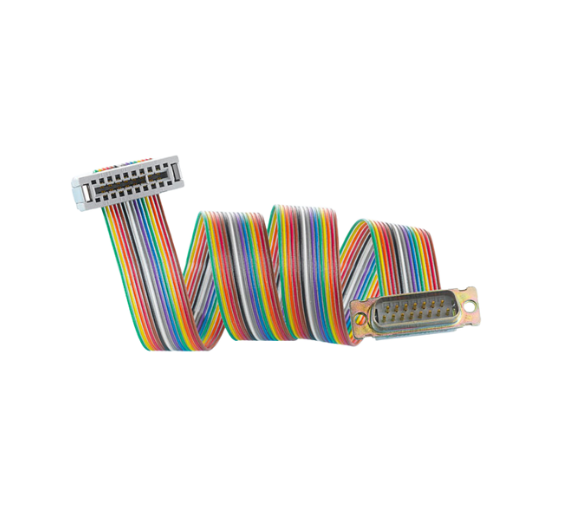

A flat ribbon cable is a multi-core cable where, unlike conventional round cables, the individual conductors are arranged parallel to each other in a single plane. The spacing between conductors can range from 0.0 mm to 2.54 mm, depending on the conductor cross-section. The most common pitch is 1.27 mm. The number of conductors in a ribbon cable typically ranges from 6 to 96. For easy identification and connection, each conductor is colour-coded according to DIN IEC 62. The colour sequence repeats every 10 conductors, depending on the total number used. Simple versions have a standard grey tone.

Flat ribbon cables with connectors provide space-saving electrical connections for electrical components. They are particularly well-suited for installation in enclosures or tight spaces. Their flexibility makes them adaptable to a wide range of environments. Parallel flat ribbon cables with multiple conductors are ideal for simple plug-in connections. The parallel arrangement of individual conductors enables easy connection via plug connectors—no splicing, soldering, or stripping required.

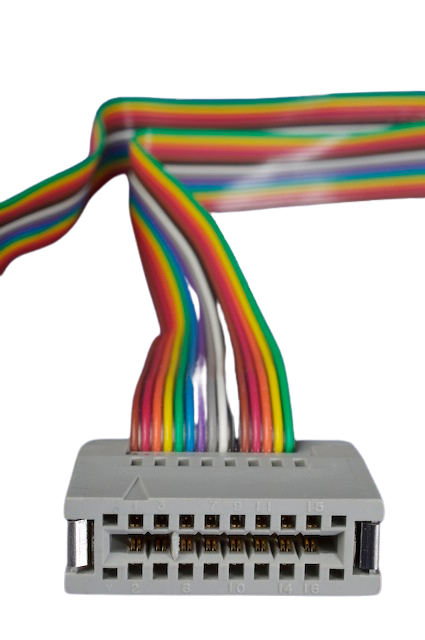

The insulation displacement technology makes it possible to connect cables with D-Sub connectors or other connectors without stripping the insulation. The connection contacts of the connectors are specially designed for the flat ribbon cables so that each strand does not have to be stripped individually. The advantage of using flat ribbon cables and insulation displacement connectors is that there is no need for time-consuming preparatory work such as stripping, splicing and soldering the wire ends to the connector contacts. There are also customised solutions for flat ribbon connectors, depending on the cable. The specifications vary and are related to criteria such as current strength, voltage force or protection against external influences.

Copper and polyvinyl chloride (PVC) are usually used in the manufacture of flat ribbon cables. The copper cables are covered with a core sheath, which also serves as the outer sheath. We also offer shielded and specially sheathed variants on request. The cables are cut to size by machine with millimetre precision. To connect the ribbon cables to the respective ribbon connectors, we use the standard cut-and-clamp technique. In this process, the flat ribbon cable is inserted into a connector with appropriately arranged insulation displacement contacts and crimped in a single operation using special pliers or a crimping tool. This means that all cores are simultaneously connected to the contacts of the connector in a gas-tight manner. We generally use standardised D-Sub connectors or connectors in accordance with DIN 41651.

What Types of Flat Ribbon Cable Are There?

Twinax Flat Ribbon Cable

One of our specialties is the Twinax cable, assembled by CiS and developed by 3M. It is particularly suitable for transmitting high-frequency signals. This high-performance Twinax flat ribbon cable offers unique properties: it is thin, flat, flexible, and shielded along its length. CiS is currently the only cable manufacturer on the market offering this technology.

Round Flat Cable

A special type is the flat round cable, where a flat ribbon cable or a flat twisted pair cable is coiled and encased in a round outer sheath. To connect it to an insulation displacement connector, the cable ends are stripped, the flat section is unrolled, and the cable is connected using a plug. Shielded versions of these flat round cables are available upon request.

Flat Twisted-Pair Cable

In so-called flat twisted pair cables, two adjacent cores are twisted together. The flat ribbon cable is divided alternately into twisted and parallel wire sections. This technology makes it possible to avoid unwanted interference between independent signals.

Our Wealth of Experience in the Manufacture of Flat Ribbon Cables

As a specialist in cable assembly, we offer customised solutions manufactured using advanced processing technologies. In addition to cutting and stripping cable ends, flat ribbon cable processing also includes punching and splicing. We assemble all standard flat ribbon cable connectors available on the market. For standard versions, production is typically automated. For customised solutions, we plan and design the appropriate cables in advance. We use both mechanical and manual processes to carefully manufacture complex assemblies.

Dive into the World of Connection Technology

Take a virtual tour of our production now and explore the variety of our products and technologies.

Contact

Your Direct Connection to Us - Personal and Competent!

Do you have a challenge for us? Then please do not hesitate to get in touch. Connections are built on trust – and that's our foundation.

Our team is always happy to assist you.